| HOME > PRODUCT > SOFT SEALING GATE VALVE |

|

Development Motives and Characteristics

(Eccentricity Relief Half Guide) |

|

| Development Motives |

Basic requirements for a valve need to interrupt fluid and to make a current to be more effluent.

This is a valve developed for meeting to economical efficiency, easy handling and convenient

maintenance & repairing. |

|

| Characteristics (No.0299719, No.029472) |

1. We reduce the weight of valve to a minimum(about 15%) considering to economical efficiency by

employing the method of half guide with the eccentricity uneven-type.

2. By designing the driving force equilibrium supporting stand with the method of eccentricity, our

valve displays constant index capacity.

3. It is convenient to post management owing to the simplification of components.

4. This valve is an environment friendly product. |

|

|

|

|

|

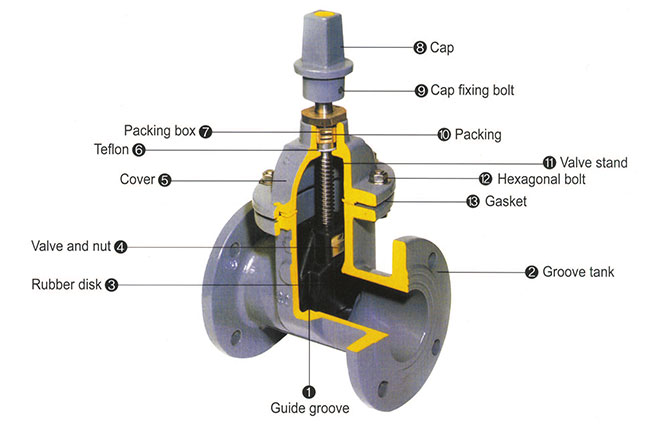

| Inner Structure |

|

|

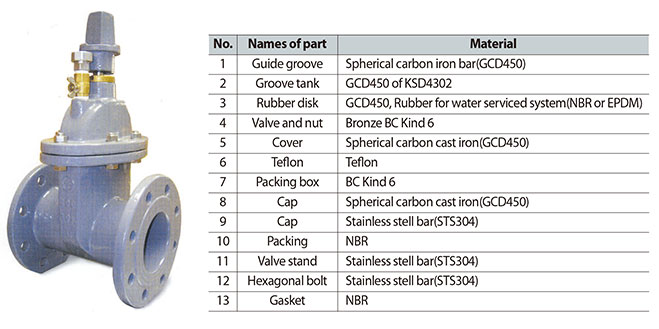

| Materials of HQ-S |

|

|

HQ-S Standerd

(Eccentricity Relief Half Guide) |

|

|

|

|

|

|

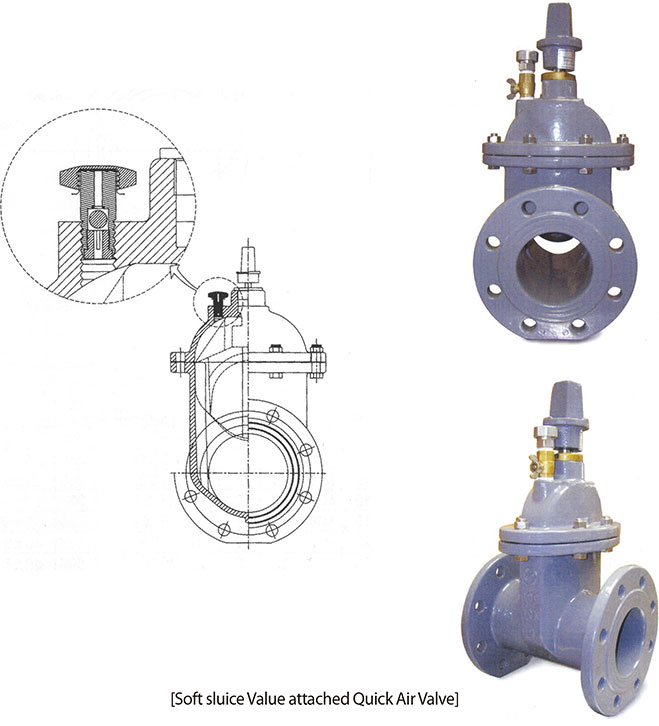

| Characteristics(Soft sluice Value attached Quick Air Valve, Patent No.0510105) |

1. It is possible to install without any restriction of special angle.

2. It shows superior deflation of air owing to the rotation of floating ball.

3. There is no clog due to an alien substance though long operation.

4. There is a difference of five times(min.) or sixteen times(max.)in the deflation amount of air.

(small size but high degree of efficiency in the deflation of air than the existing air valves)

5. This is a quick air deflation valve with low cost but high degree of efficiency. |

|

|

|

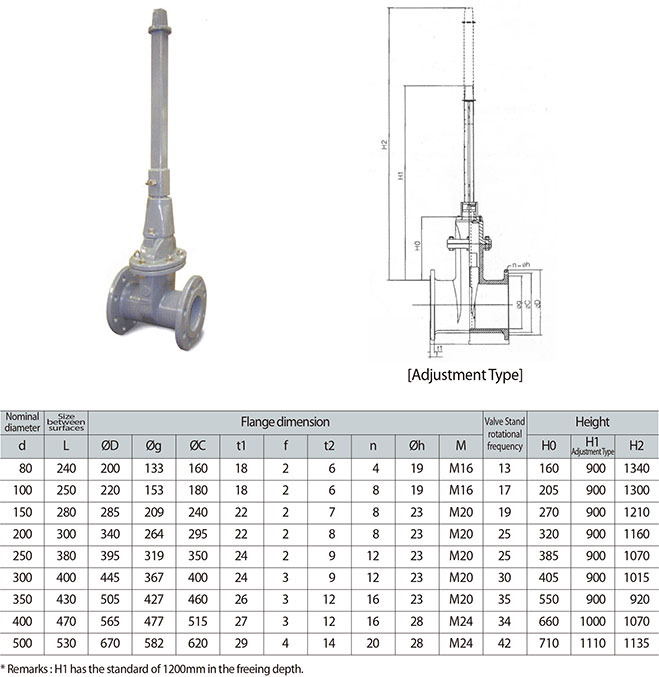

| Characteristics of Cap Adjustment Type |

| Characteristics |

1. This is designed based on the freezing depth.

2. The Adjustment type is able to adjust the heigh minutely besed on the freezing depth.

3. After installing this valve, it is easy to operate the open or close of fluid route.

※ The height is able to be changed as the request of customer. |

|

|

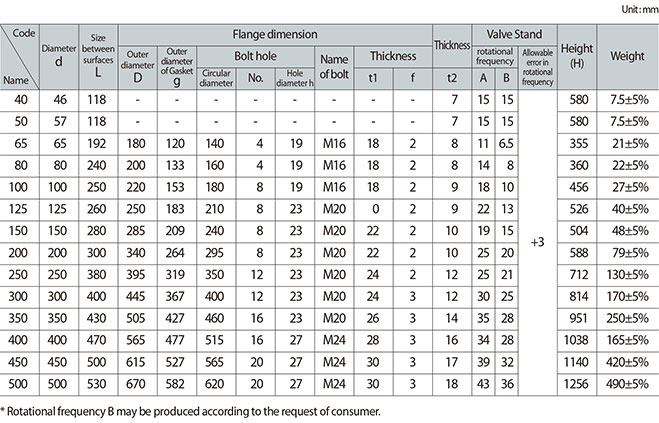

Specifications for procurement

(Eccentricity Relief Half Guide) |

|

| Major materials |

| The major materials shall conform to the approve drawings of high grade soft water stop valves dor

controlling fluid (HQ-S)(Patent No.0299719)and the specifications in Page B(Table 1-1) |

|

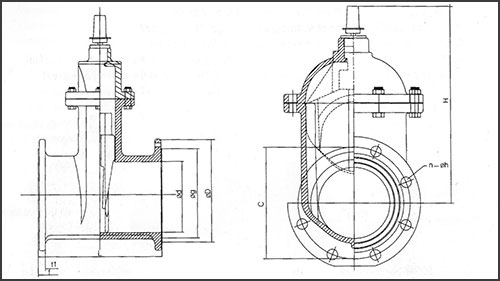

| Out shape |

Outer shape before painted

The surface of a mould shall be so smooth that it will keep from any kind of disadvantages in use such

as crack, groove, browed groove, and the like.

Outer shape after painted

The surface of a valve shall be free from any kind of faults such as mixture of foreign materials, mistake

of painting, pin hall, and the like. |

|

| Painting |

| The cast iron parts of a valve shall be painted in all and the colors shall be grey or one demanded by

a customer. Painting materials, painting parts, and painting method shall conform to the Annex of

EM0368(Method for spray painting epoxy resin to a soft valve of water service). |

|

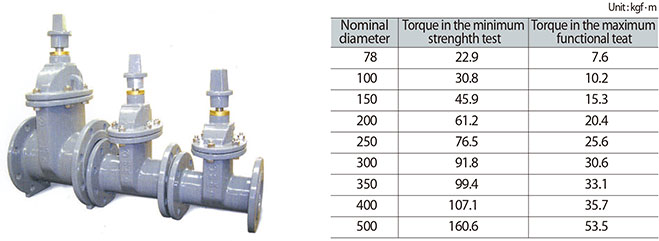

| Inspection and execution |

Strength test

A valve shall be free from any damage in the stem or the upper part of the stem cap under a condition

that a different pressure will be applied upon a full closure of the disk that will be impossible to operate

a torque in a maximum functional test stated in Table 1-2, and the damaged status shall be confirmed

though the following functional test.

Functional test

Manipulate in to go and return between the full closure by deploying the valve after a strength test when

a manipulation torque of the whole distance shall not exceed a torque of the maximum functional test. |

|

|